10-25kg waterless ghee packaging line commercial butter packaging machine

(12139 review)

Category: Margarine packaging line

- Description

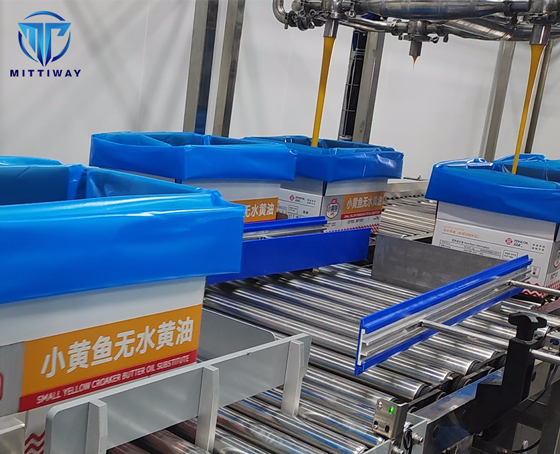

For the large-scale packaging needs of oil products such as Margarine, Butter, Shortening, and Palm Oil, we launched a full-process automated packaging line, focusing on 10-25kg box packaging scenarios, integrating four core equipment to achieve seamless connection from unpacking, filling to sealing, and create a stable, efficient and hygienic production chain for food processing companies.

Highlights of core equipment

1. Carton Erector

Intelligent molding: Equipped with a servo motor drive system, it can quickly grab folding cartons, accurately complete the bottom folding and tape sealing, and is compatible with a variety of box types (standard boxes/special-shaped boxes). The unpacking speed reaches 15-20 boxes/minute.

Flexible adaptation: Equipped with a photoelectric detection device, it automatically identifies the size deviation of the carton, adjusts the movement amplitude of the robotic arm in real time, reduces carton loss, and ensures packaging consistency.

2. Bag Inserter Machine

Aseptic operation: It adopts all-stainless steel frame and food-grade contact parts, supports automatic delivery of polyethylene (PE) or aluminum foil bags, and has a built-in dust removal system to ensure that the bag is clean and free of impurities.

Precise alignment: Vacuum suction cup + mechanical gripper dual positioning to achieve rapid nesting of bags and cartons, adapt to bags of different thicknesses, and compatible with the pre-packaging needs of oil products.

3. Automatic Filling

Multiple metering: According to the characteristics of oil products, it provides plunger quantitative filling (applicable to solid/semi-solid) and flow meter filling (applicable to liquid palm oil) dual modes, with an accuracy error of ≤±0.5%.

Anti-stick design: The filling head adopts Teflon coating and heating and heat preservation function to avoid grease condensation and wall hanging, supports 10-25kg specifications for rapid switching, and improves production efficiency by 30%.

4. Automatic Sealing Machine

Double-effect sealing: First, the inner bag is sealed by hot pressing technology, and then the high-frequency vibration sealing machine is used to seal the top of the carton with tape. The double protection ensures that the product is leak-free, moisture-proof and dust-proof during storage and transportation.

Intelligent detection: Integrated weight re-inspection and sealing flatness sensors, unqualified products are automatically removed, reducing manual intervention and improving quality control efficiency.

5. Case Sealer

High-speed linkage: Seamlessly connected with the front-end equipment, the "I"-shaped tape sealing process is adopted to ensure that the six sides of the carton are stable, and the sealing speed matches the rhythm of the entire line, supporting continuous 24-hour operation.

Data traceability: Equipped with an industrial-grade PLC control system, it can record the weight, sealing time and other data of each box of products to meet the needs of food safety traceability.

Advantages of scenario-based solutions

Hygiene compliance: The easy-to-disassemble and clean module design meets the high-cleanliness production requirements of oil and fat products.

Flexible switching: Through parameterized program settings, the packaging process of different products (such as butter vs shortening) can be quickly switched, and the changeover time is shortened to less than 15 minutes.

Cost optimization: Compared with traditional manual packaging, the entire line can reduce 60% of labor input, reduce the waste rate of consumables to less than 5%, and save more than one million yuan in annual comprehensive costs.

One-stop intelligent upgrade, making every box of fat a quality benchmark

Whether it is the bulk supply of baking ingredients or the large-scale packaging needs of the catering industry, our automated packaging lines can give your products a reliable "coat" with stable performance and precise technology. Consult now to unlock the efficient productivity of fat packaging!

Search Keyword

Category

Latests

-

5-25kg Bucket-Packed···

(622 review)

-

10-25KG Animal Butte···

(1180 review)

-

Automated packaging ···

(7159 review)

-

20kg water-free ghee···

(12033 review)

-

10-25kg waterless gh···

(12140 review)

-

Margarine and butter···

(12176 review)